When discussing operations management, components of operations management take major importance in the subject. It is vital to identify what has created the operations management field.

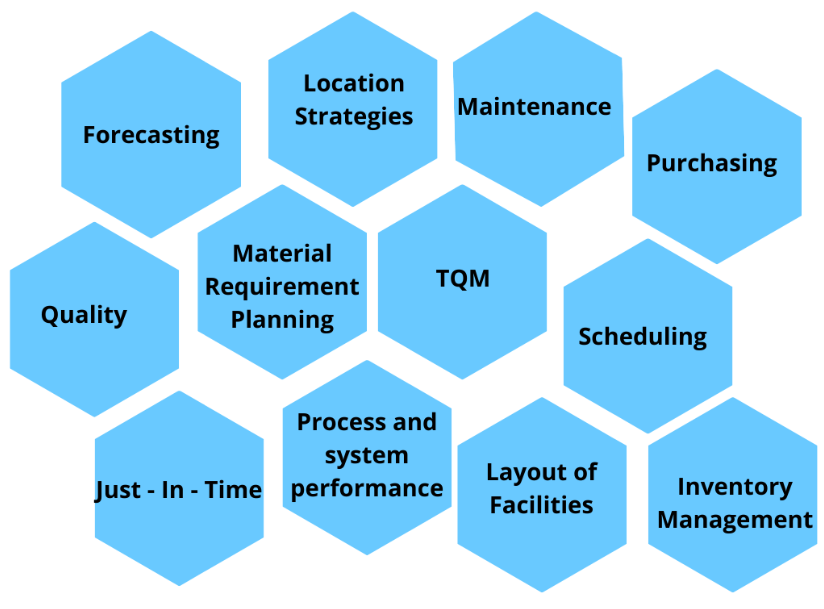

There are 12 main components of operations management that can be identified. The picture below depicts the 12 components of operations management.

Forecasting– This component is related to using the organization’s historical data, facts, and figures, collected statistics, and details when making production decisions. These decisions are made for future productions based on the past data available. Accurate forecasting should be able to decide the production volume that is necessary for a specific time period. This will help the business to avoid maintaining excess inventory with the company or face shortages in the inventory in the production process.

Location Strategies – This is considered one of the important components of operation management. The business has to select the right location for its existence and growth. There are many factors that need to be considered when selecting the right location for the business. Business should be located in a place where it can easily access the raw material for the production, it should have enough space to maintain inventory, costs such as transportation should be reasonable, the environmental factors should be favorable (weather conditions, political and economical conditions) and it should have convenient access to the target market. Apart from these identified factors, the business should be established in the selected place at a reasonable cost.

Maintenance – This component highlights the importance of scheduling all the regular maintenances, checks, and adjustments for the machinery and equipment related to the production process. This is to ensure the safety of the production process as well as improve quality and productivity. Regular maintenance checks can avoid sudden injuries, breakdowns, and failures. Apart from that, it helps to maintain the quality of the output as well.

Purchasing – This is also considered one of the important components of operations management. This component ensures that the business organization has enough raw materials for production to supply the future demand from the market. Purchasing raw materials can be done as a centralized, decentralized, or a combined strategy.

Centralized purchasing is when a single department is responsible for purchasing raw materials for the entire production process. Decentralized purchasing is when each department or branch in the production process purchases their own raw materials separately based on their individual needs.

Scheduling – This component is about assigning the correct job role to the correct party. It can be to the employees or to the machinery. Assigning the most suitable responsibilities to the correct party helps to increase the productivity of the production process and also minimize or eliminate the faults. This can help the business to reduce costs, increase revenues, and to achieve a competitive advantage in the market.

Total Quality Management (TQM) – This is a strategy used by businesses to create a customer-focused and faults free production process that can help to increase the customer satisfaction level. The main focus of total quality management helps the business to maintain proper supply chain management in the entire business process and achieve the organizational goals with continuous improvement.

Material Requirements Planning (MRP) – This component ensures that the production process is receiving the right material at the right time in the right amount to ensure a smooth production process and timely completion. It involves identifying the currently available inventory and realizing the additional material requirements and scheduling the purchasing process.

Quality – All the components of operations management get connected with this component as it is important for any business to maintain overall quality in the entire production process. Quality helps the business to carry out a smooth production process and to achieve brand loyalty from the customers.

Just-In-Time (JIT) – This component helps the business process to start the production process just-in-time to release the final product to the market without any delay. This technique ensures that the business is limiting the number of work-in-progress inventory in the business and reduce the inventory requirements of the business.

Process and system performance – This is one of the major components of operations management that is measured through examination, utilization of capacity, or the production process. The business has to analyze and compare the expected quantity and the time that takes to produce in order to get a sense of whether the production process is achieving the set targets or not.

The layout of facilities – This component is set to ensure the use of the most optimal workflow in the production process. The layout should make sure the minimum motion of items.

Inventory Management – This component explains keeping a proper record about the materials and other items in stock to make sure the supply chain management process is continuing smoothly. Effective inventory management will ensure meeting the customer demands by providing the required amount of products to the market when necessary without excess or a shortage.